Our Company

Looking for quality book printing at an affordable price?

You’ve come to the right place.

ABOUT US

Since 1973 our company’s niche has been short-run and ultra short-run book printing; we are a single source provider for short-run publishers, small presses, authors, university presses, and others. We also offer Instant Quote which is an easy to use budgeting tool, as well as inventory management, Ship-On-Demand Fulfillment, Print-On-Demand, and warehousing.

Total Printing Systems shares your commitment to the protection of the environment. We are FSC® certified. We use environmentally friendly digital inks (98% water) and toner and always stock recycled paper. We continue to make improvements to our practices in order to lessen the impact on our environment.

Our forward-thinking company is always looking for continuous improvement. Located in the Heartland of America (Newton, IL), we remain dedicated to customer satisfaction.

OUR SERVICES

- Instant Quote Internet Based Pricer

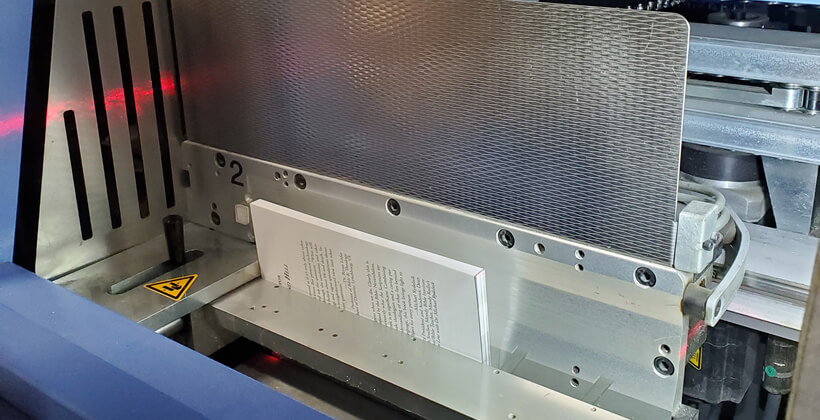

- Digital Short Run Book Printing

High-Speed Inkjet Web, Sheetfed Toner, Full Color, and Black & White

- Complete In-House Bindery Saddle Stitch, Perfect Binding, Case Binding (adhesive and Side Sewn), Mechanical Binding (Spiral/Wire-O/Comb), Loose Leaf, 3-hole drill, Lay-flat, and PUR Binding

- Print-On-Demand Just-in-time manufacturing model that allows for a single book to be manufactured at a time.

- Various Cover and Finishing Options Foil Stamping, Matte Varnish/Spot Gloss, Embossing, and Debossing

- Lamination Gloss and Matte

- Ship-On-Demand Fulfillment

- Warehousing

- Inventory Management

- eBooks

OUR NICHE

Books: Short-run & ultra short-run digital book production.

We specialize in short-run case binding completed in-house.

Our company provides digital sheetfed and digital web using state of the art equipment.

QUALITY OPTIONS THAT FIT ANY BUDGET SETS TPS APART.

When printing in color, there is little difference in the image quality between Textbook and Coffee Table Quality due to our recent upgrade to a Canon Océ ProStreamTM web press. Choose Textbook Quality to receive the best price on higher quantities.

Textbook Quality

TPS has two presses that produce Textbook Quality. Our Truepress Jet520HD Mono is best if your project is single color black text. This choice is commonly used for trade paperbacks, reference books, and instruction manuals. For Textbook Quality that requires color or B&W photos printed hi-res, TPS has installed a Canon Océ ProStreamTM web press which produces vibrant color and high quality reproduction of photos. It is the perfect choice for children’s books, catalogs, cookbooks, and conference materials. Contact a representative about your project’s specific needs.

Coffee Table Quality

Coffee Table Quality should be used when the highest quality we can produce is needed. It is normally used when a project has many full color and high resolution photographs or very heavy coverage throughout. Coffee Table Quality is produced on our sheetfed loner presses. These presses also produce covers and jackets.

To insure the lowest price, and highest quality, at Total Printing Systems, we have a complete in-house bindery department that includes Saddle Stitching, Perfect Binding, Case Binding (adhesive and side sewn), Mechanical Binding (Spiral/Wire-O/Comb), Loose Leaf, 3-hole drill, Lay-flat, and PUR Binding.

MEET THE CREW

Like most successful companies, the vision of the owners and management for Total Printing Systems is complemented by each and every employee’s capacity to execute his or her role, know the state-of-the- art equipment, and adapt to unique requests which continue to make printing true to its history – An art. The employees at Total Printing Systems are the lifeblood of the company. With a hearty Midwest work ethic, this CREW consistently meets the craftsmanship standards and production turn demands which set the bar for the competition. Take a moment to meet the crew.

OUR CLIENTS & TESTIMONIALS

OUR CUSTOMERS

Total Printing Systems does not just refer to you as a customer. We consider every business opportunity a chance to establish a long term partnership. Our goal is loftier at Total Printing Systems than the traditional customer-supplier model in this industry. We want to establish new friendships as well. Our customers become print partners.

Our print partners range from young to well-seasoned, from micro publishers to large fortune 500 companies. Whether you have one title or are an established publisher with tens of thousands of titles, you can have confidence in Total Printing Systems as a capable, cost-effective, and conscientious candidate for management of your project.

SOME OF OUR CUSTOMERS INCLUDE:

- Self Publishers

- Trade Book Publishers

- Religious Publishers

- Education Publishers

- University Presses

- Government

- Manufacturing

- Broker / Distributors

- Insurance Industry

- Authors

- Small Presses

TESTIMONIALS

Meg, From our initial conversation early on Monday morning, July 11, I felt TPS was the right choice to print a short run of the hardcover book: Feathered Friends, by author-illustrator Madelyn A. Lee. Your customer service approach was outstanding: Your knowledge of TPS' printing options and processes; realistic view of timelines; and your responsiveness.

You LISTENED to my description of the book and offered your professional advice on the best paper for quality in a children's book with a lot of art; you answered every detailed question I asked; and, most importantly, you LISTENED to my self-induced dilemma of having scheduled a debut book signing for the author-illustrator with a fairly short timeline because she was leaving for college. As the project manager, Lori, I so appreciated your commitment to understanding the criticality of the timeline, to knowing where the book was throughout production, and to open communication via phone and e-mail.

The quality of Feathered Friends, printed by TPS, is absolutely superb. The quality reflects the people who work at TPS, and I would appreciate your thanking all of them for me.

We recently received the latest round of our title, “God’s Amazing World.” I could not believe the image quality of this full color book from your new press. I loved the original print run on this title and did not anticipate this kind of jump in quality on the latest run. The image definition and richness of color on the second run was simply more than we could’ve asked for. We had a very big vision for this title and how it would look, your team and the new press surpassed even our expectations of what the book would be. Thank you for all your teams hard work and we look forward to other titles coming off of this press in the future.

Please share with everyone on the team how thrilled we are with the quality of the printing for Cian From the Philippines! The photos look even better than what we were accustomed to seeing. We can’t believe the detail and sharpness, and the brightness of the colors.

We are confident that this book will be successful and look forward to many future printings with you. We are still working on the website and will be sending out the book for advance reviews at the end of January.

Happy New Year!

I want to thank you both for the outstanding service and the wonderful book I received last week.

I have to admit that I was a bit leery about getting my book printed with a company out of state and one I found online. Your company exceeded my expectation by a mile and I’m so please with the way my book came out. The price was right and the service outstanding….what more can you ask for.

Awesome job and look forward to doing business with you again. Take care.

Thank you for your always prompt and efficient service.

Mike Ammirata called on me faithfully for several years before I started using your printing services. Patience pays off! Every one of your employees whom I have interfaced with has been extremely friendly and and efficient. You may not realize how important your jobs are to making one’s life more enjoyable and rewarding. I just thought you all ought to know that, but I am sure you already do.

Wow! The long journey was less painful because of your amazing help, and encouragement. TPS is so fortunate to have you as an employee, and I was so fortunate to have you as my rep.

What an exciting day in my life! The proof arrived this morning, and it is SO BEAUTIFUL. We all worked hard; but the results made the hard work worthwhile.

First, let me tell you how much I appreciate working with your group. Every “t” is crossed and every “i” dotted, and that’s exactly how I like to work.

You guys have been amazing. Picked up the books. As always, fantastic job!

Printing books is the one aspect of this journey I have not had to worry about since I started using Total Printing some 5 years ago. You guys are absolutely the best in the industry.

Believe me, just as soon as we complete the first round I’ll be calling you for the job. On the other hand I love my books. Thank you and your crew for all of your efforts and hard work. What a Team!

Thank you so much for pushing our reprint book Intro to Rec Serv with Disabilities – thru FAST! Sagamore appreciates the work that Brenda, Cindy and Charlie do!

It is people like you all, that make our job easier!!!!!

Thought you would like to read the note below. You are making grown up people cry!!!!!!!!!!!!!!!!!!!!!!!!!!!

“The printed proof of the book arrived yesterday! I took a look at it last night, with my client, Mark. It looks AMAZING! He was so pleased that he got a little teary-eyed! We both are thrilled with the quality of printing…it is beautiful!”

I am blown away. It’s difficult to express how happy I am with the book. It’s literally perfect and it’s exactly how I imagined it in my head back when we started this project in… March? Anyway, I am very pleased with the product, all of you did an amazing job. I’ve already got some cigar shop owners very interested in putting it in their stores, so stay tuned as I may be back soon to order more books in higher quantities.

Books arrived. They look great, I’m really happy. Thank you very much.

Once again thank you. Y’all’s service is great.

I just wanted to let you know we received the foil swatches you sent, and this afternoon I am going to take them over to the designer. Once again, I just have to say I really appreciate your responsiveness. It’s one of a great many reasons I keep coming back to TPS.

They got here early this morning & they look fantastic. Thanks so much to everyone at TPS for the effort & support. I’m sure our interns will be thrilled.

The books for this title arrived today and they look great. We are happy with how the cover turned out. And we really appreciate how quickly the books were printed and shipped.

Thanks for getting my Mexico Boating done so quickly. Thanks for another successful print run, you’ve made another happy customer!

The books arrived in Rome, and we want to take a moment to thank you. This was a very fast turnaround, and while we hope to avoid that kind of time pressure most of the time, it was just amazing that and how you were able to handle it. A big THANK YOU for all involved.

We’re absolutely thrilled with the quality of the finished books, but more importantly so are our customers.

This was my first time handling the printing side of our company and, while I’ve no doubt been annoying with my numerous changes in quantity and paper type, you have both been absolutely brilliant. I know lots of good folk were involved behind the scenes at TPS fulfilling our order, but you’re the faces of TPS for Triple Ace Games.

Those books look great!! Our Compliments to your entire staff!!

I just wanted to let you know that we received the books last week and they look great. It was a pleasure to work with you both on this project!

Thanks so much for having all requested titles here by April 1 and early. I really appreciate the impeccable job you always do for us.

You did it all-the RIGHT way-I wish everyone did.

You have a great team over there!

Thank you very much for all your help and guidance in the process of preparing my book for the production printing. Now it’s on the way with FedEx

You’ve been very helpful, and I appreciate that.

I will definitely get back to you if I need to print more or, even better, if I”ll have another book to publish.

I love your company culture. Everyone is so honoring to each other. I’m sure it’s a great place to “work”.

I just wanted to let you know that the three latest titles have arrived and the books look really, really nice! Just great! You do such quality work over there at TPS and we want to say thank you for doing things so well. Thank you so much!

Working with your team and experiencing such consistently good results brings us great peace of mind. Your capable style ends up saving us a lot of time and the excellent pricing saves us money; we just couldn’t ask for a better experience!

We just received samples of the Packing for Travel books and they are gorgeous.

As always, thank you so very much for meeting these seemingly impossible deadlines and always making us proud of the end product.

Know you are appreciated and please pass along to your entire team!

Thanks. The ‘estimator’ site is slick.

TPS is a great company. The best I have ever worked with on every book you have done for me in the present and the past.

I met with my client yesterday after he took delivery of his new Space Mineral Resources books, and I have to let you know how pleased he was. Having worked as a salesman for Jostens, and having worked on many case bound book projects, I just have to say your quality is the best in the business. Though production techniques have changed significantly over the last few decades, and these days we rely upon modern digital technology, great printing is still all about craftsmanship. I only have the pleasure of interacting regularly with Darrin, Melinda and sometimes Donna, but if I was able to someday take a tour of your production facility, I would be happy to shake the hands of all your production personnel, and give them a sincere, “Job well done!”

Thank you so much for taking such great care of me and my clients!

Thanks for turning this around so quickly. I know I can count on your quality and professionalism.

Thank you two for all you do for us. You both fit a certain need for us. We know who to go to for our books and such. You always do a great job and keep your promises. Kelly and I really do appreciate it. You both are great partners of ours.

Client is in LOVE with these. Thank you for making them great!

Once again thank you for the printing of, “Gallery of the Bible”. We have heard amazing comments on the book and how it was printed!!!!!!

I cannot tell you how thrilled we are with the Mashomack programs this year. TPS always does a great job but this year the quality of the paper and the sharpness of the printing is truly outstanding.

I really don’t know what we would do without you and your entire team who work so hard to always meet our deadlines and produce an outstanding product every time.

From all of us, to all of you,

I’d like to thank you for your prompt, cordial and professional service. All of the TPS team have been great as well. I hope that you all enjoyed a restful and pleasant weekend. I should be back to plague you all soon with the reworked Book 1.

You’re always in the running with your quotes, and we do the vast majority of our paperbacks with you. I’m a big fan of your operation and recently recommended you to another publisher friend. Thanks for reaching out.

Just viewed the printed samples. All we can say is WOW! It is beautiful!

Thanks, we have been very pleased with the prompt service from your company. Lori is on the ball. We may go with another size on our next reprint so that was behind this quote. Thanks for staying in touch.

We got the books yesterday and they all look wonderful! Thank you so much for your help. We will definitely be coming back for another run of the books in the near future.

Just to say the boxes of books arrived and they are terrific. Great job. Looking forward to new orders & new projects. You folks are top shelf professionals.

Very good service & wonderful finished product.

Quick note to let you know that the books arrived in time of my customer’s book launch – the books look awesome! She sold 60+ at the event. Many thanks to TPS for producing a great looking book & delivering it on time!!

I received lots of great feedback about the yearbooks. Nice work. Have a great day.

We appreciate the quality and the price, you guys are tops.

HISTORY

Total Printing Systems, a family owned business that was established in 1973 by Rich and Wendy Lindemann, is proud of our history. Originally founded to provide commercial printing, Total Printing Systems rapidly expanded to include governmental publications in the mid 1970s. We utilize and greatly benefit from having a rural community workforce comprised of dedicated employees and driven by a strong mid-western work ethic that ensures a quality product.

We are committed to pushing technology further, utilizing the strengths of that technology and combining those strengths with decades of experience in the book manufacturing industry. The result of this combination of technology and experience has brought Total Printing Systems to the forefront of the book manufacturing industry.

1973

Total Printing Systems (TPS) was established by Rich and Wendy Lindemann as a general commercial printer.

1977

TPS saw the need to develop a niche to be successful, so we began a relationship with the Federal Government Printing Office producing forms, short run books and manuals.

1979-1993

TPS experienced rapid growth and took our sales from $69 thousand to 11 million dollars annually, primarily producing shorts runs for the Federal Government Printing Office (GPO).

1994

The internet, although still in its infancy inspired us to take the company in a new direction. When “On Demand” wasn’t even a buzz phrase yet we had developed customized equipment, which enabled us to produce over 13,000 orders per year for GPO. This equipment gave us the niche to get back into the commercial market, specifically short run and micro run book printing. We spent the next few years planning and developing ways to distinguish ourselves from other commercial book printers.

1997

TPS launched an internally developed internet-based pricing tool (See Instant Quote). We used this tool initially as an exclusive tool for a quick printing franchise, then several years later we opened the tool up to the general public. We also installed our first direct-to-plate system.

1999

A new fulfillment and distribution facility was built.

2001

TPS worked with Scitex (Kodak) to implement the operation of a continuous high-speed inkjet press designed for a book manufacturer (VersaMark). This partnership led to the first digital inkjet based web press installed for book printing in the world.

2005

TPS combined our manufacturing facility and distribution facility by moving from our original location to 201 S. Gregory Dr., Newton, IL. We also installed our second Kodak VersaMark digital web.

2006

TPS updated our bindery with new perfect binding and saddle stitching lines. We also updated our cutters and added a Nexpress 2100 Plus press (5 color).

2007

TPS updated our direct to plate system and added adhesive case binding, foil stamping, and embossing.

2008

TPS installed our second Nexpress and added side sewing to our case binding operation.

2009

TPS installed one of the first Screen TruePress Jet520 presses in the USA. It is a full color digital ink based web press running up to 420 ft. per minute. This press allowed us to produce full color books at up to 720 x 720 dpi.

2010

TPS installed a new in-line Hunkeler finishing system which converts rolls of printed product and book blocks for final finishing. We started a new division for POD production. This true Print-On-Demand facility is currently shipping over 50,000 books per month.

2011

TPS added PUR perfect binding for coated papers and lay-flat finishing.

2012-2013

Increase in case binding demand led us to bring in additional higher speed adhesive case binding equipment. We also added additional 4 color process and B&W toner based printers.

2014

The need for additional, higher speed, higher resolution B&W production brought us the Screen Truepress 520 EX Mono with Hunkeler finishing. In order to bind the longer runs that the higher speed press could offer, we installed a CABS4000 perfect binding line. We also installed a more automated head and tail band machine and the first fully automated Technograph Pronto endsheet maker in the US. This machine allows us to efficiently produce printed endsheets for hard cover books.

2015

Toward the end of 2015, we upgraded our cover press to a new Kodak NexPress SX3300. In addition to an increase in image quality, this press also allowed us to perform a dimensional clear toner coating that can give your cover a unique texture. Another added benefit is the addition of an extended sheet feed capability, which now allows us to print on up to a 14×39″ sheet, printing to 13.375×38.5. This is especially important for larger format case bound covers and dust jackets.

2016

On September 30th, 2016 Rick Lindemann purchased majority ownership of Total Printing Systems from his parents and they officially retired from the company.

2019

TPS installed the Canon Océ ProStream. Canon’s innovations in the digital inkjet printing industry led to a four-color image quality unrivaled by any inkjet technology at the time. Still in operation today, the Canon ProStream continues to deliver a beautiful image to our customers.

2020

TPS installed two Muller Martini Vareo perfect binders, increasing overall efficiency and capacity for binding with PUR glue.

2022

TPS added on a 25,000 sq. ft. fulfillment warehouse to the Newton manufacturing facility, moving fulfillment and POD services to the same location as our general short-run services.

2023

Celebrating our 50th year in 2023!

Seeking to improve efficiency in multiple departments, TPS installed a Digibook Mitabook casing-in machine to further streamline the casebound book-making process, as well as an Autobond Micro 52 TH-PH laminator, which doubled TPS’ gloss and matte lamination output. Last but not least a Truepress Jet520HD Mono was installed to increase the quality of single color black printing.